China Zhengzhou Zhongyue Silicon Carbide Electric Heating Element Manufacturer

TEL:+86 13523030448

Email:xy9962@163.com

This paper summarizes the characteristics of silicon-molybdenum electric heating element, the characteristics of silicon-molybdenum electric heating system, and the debugging method of silicon-molybdenum electric heating system and the matters for attention in use.

I. Characteristics (physical and chemical properties) of electric heating element of silicon-molybdenum rod;

1, silicon molybdenum rod at high temperature (above 1500 degrees) some softening, hard and brittle at low temperature;

2, silicon molybdenum rod resistance heating element is a kind of high temperature resistance, oxidation resistance heating element made on the basis of molybdenum disilide, with unique high temperature oxidation resistance.

3, in the oxidized atmosphere, the highest use temperature is 1800℃. The resistance of silicon molybdenum rod electric heating element increases rapidly with the increase of temperature, when the temperature is constant, the resistance value is stable. Under normal conditions, the resistance of the element does not change with the length of time used, so the old and new silicon molybdenum rod heating elements can be mixed. (Resistance temperature coefficient)

Second, the general silicon molybdenum rod electric heating system

1, silicon molybdenum rod electric heating system electrical components generally have transformers, and is used for voltage reduction.

The resistance temperature coefficient of silicon molybdenum rod is larger than the general electric heating element. At room temperature, the resistance value is very small. If high voltage is added, the silicon molybdenum rod will be burned out by large current. After the temperature rises, the resistance of the electric heating element of silicon molybdenum rod increases rapidly with the temperature rise, then the voltage can be increased. Therefore, the voltage of electric heating of silicon molybdenum rod is generally supplied through transformer step-down to protect the silicon molybdenum rod from damage.

2. The control mode of silicon-molybdenum rod electric heating system should be triggered by phase shift

Silicon molybdenum rods of electrical heating control method should adopt phase-shifting trigger mode, because of the zero passage trigger on-off control mode will load on the silicon molybdenum rods of inverter voltage transformer secondary side, the voltage will be superimposed on the output voltage, will produce larger voltage load on electric heating silicon molybdenum rods, and produce large current, lead to damage of silicon molybdenum rods.

Three, silicon molybdenum rod electric heating furnace heating steps

1. Electric heating furnace can officially start heating after baking.

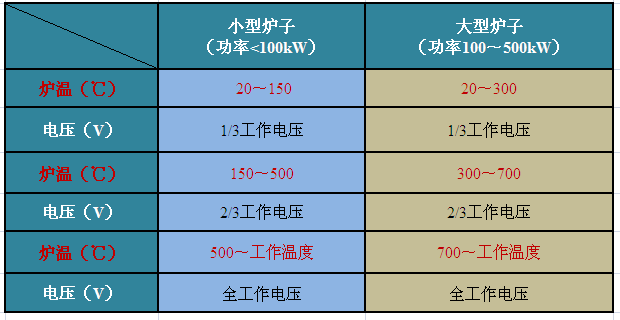

In order to avoid damage to electrical equipment caused by excessive current impact, it is recommended to use the following steps and parameters to start the electric furnace:

Note: The time should not be too long when shifting gears. The temperature of general components should not drop by 300C ~ 400C, otherwise, it is easy to cause current shock and damage to electrical equipment.

2. Electric heating process of silicon molybdenum rod in high temperature electric furnace (actual usage parameters)

The electric heating process of silicon molybdenum rod in high temperature electric furnace is divided into two parts:

1, less than 300 degrees according to manual output temperature control;

2, when the temperature is greater than 300 degrees, switch to the time program temperature control.

(1) When the temperature is less than 300 degrees, the temperature is controlled by manual output

Start to power on, switch to the manual state, adjust the output value to 5%, and observe the current in real time (the current is the actual current of the load, note the difference with the current displayed on the KSY-P interface), 10% above 50 degrees, 25% above 100 degrees; The current in the first 20Min does not exceed 50A, that is, 1/3 of the operating voltage; The current in the first hour does not exceed 100A, which is 2/3 of the operating voltage. Note: Heat up below 300 degrees in this way.

(2) When the temperature is greater than 300 degrees, switch to the time program temperature control

After manually adjusting the temperature to more than 300 degrees, switch to the time program mode and control it according to the time program. The control parameters are set as follows:

Four, silicon molybdenum rod electric heating precautions

According to THE structure, WORKING atmosphere and temperature OF the heating equipment, the correct selection of the surface load of the heating element is the key to the service life of the silicon molybdenum rod heating element.

1, silicon molybdenum rod heating element, should not be used in the temperature range of 400℃ to 700℃, because in this adverse condition, the element will occur low temperature oxidation resulting in element damage, powder;

2, silicon molybdenum rod heating element is suitable for use in air, neutral atmosphere, reducing atmosphere such as hydrogen will destroy the protective layer, chlorine and sulfur vapor has direct damage to the element;

3. The heating rate of silicon-molybdenum rod should not be too fast, which is actually 4℃/min in the case;

4. Pay attention to the load current when heating silicon molybdenum rod.